Polypropylene spunbond nonwoven fabric, often referred to as PP non woven fabric, is produced using a state-of-the-art spunbond process that transforms polypropylene resin into a versatile fabric. The manufacturing process begins with melting polypropylene pellets, which are then extruded into continuous filaments. These filaments are laid out in a web formation and bonded together through a combination of heat and pressure, creating a nonwoven fabric that offers exceptional strength and durability.

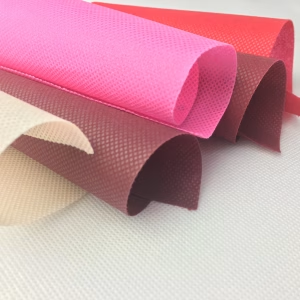

The PP spunbond nonwoven fabric boasts excellent tensile strength and tear resistance, making it suitable for a wide range of applications. It is also highly resistant to moisture, chemicals, and UV rays, which adds to its longevity and performance. This fabric is available in various weights and thicknesses, allowing for customization to meet specific requirements. Its nonwoven nature provides a uniform surface without the need for additional finishing processes, ensuring consistency and reliability in every batch.

One of the key features of PP spunbond nonwoven fabric is its unique structure. Unlike woven fabrics, which have interlaced threads, nonwoven fabrics are made by mechanically, chemically, or thermally bonding fibers. This structure provides several advantages, including enhanced tear resistance, improved flexibility, and excellent air and water permeability. The fabric’s lightweight nature, coupled with its high tensile strength, makes it suitable for demanding applications where durability and performance are crucial.

PP spunbond nonwoven fabric is also known for its low environmental impact. The production process generates minimal waste, and the fabric is often recyclable, contributing to a more sustainable approach to material usage. Its inherent properties, such as resistance to water, chemicals, and UV radiation, further enhance its appeal in various sectors. Whether used in agricultural applications for weed control, in medical settings for protective clothing, or in packaging for its strength and reliability, polypropylene spunbond nonwoven fabric proves to be a versatile and valuable material.